How to Identify Chemicals Hazardous to Health at the Workplace

Chemicals are part of our everyday life. Some are natural, like water and salt, while others are man-made, like solvents, paints, and cleaning agents. These man-made chemicals may fall into chemicals hazardous to health category. However, not all chemicals are dangerous, just like food, some are harmless, some are harmful if taken too much, and some are poisonous.

To make it easier to understand the risks, chemicals are grouped into categories under the Globally Harmonized System of Classification and Labelling of Chemicals (GHS):

- Physical hazards: chemicals that are flammable, explosive, oxidising, or reactive. Example: petrol (flammable), ammonium nitrate (explosive).

- Environmental hazards: chemicals that are harmful to the environment, especially aquatic life. Example: pesticides or mercury compounds.

- Health hazards: chemicals that can directly affect human health by causing irritation, poisoning, cancer, or damage to organs.

For workplace safety, our main concern is with chemicals hazardous to health. These include substances that can:

- irritate the eyes, skin, or lungs,

- cause poisoning or damage to internal organs,

- trigger asthma, allergies, or reproductive harm,

- and in some cases, lead to long-term diseases such as cancer.

In Malaysia, the Occupational Safety and Health (Use and Standards of Exposure of Chemicals Hazardous to Health) Regulations 2000 (USECHH) defines:

- Chemicals as chemical elements, compounds, or mixtures, natural or synthetic, excluding micro-organisms.

- Chemicals hazardous to health as those listed in schedules I and II of the Regulations, possesses any of the properties categorised in Part B of Schedule I of the Occupational Safety and Health (Classification, Packaging and Labelling of Hazardous Chemicals) Regulations 1997, comes within the definition of ‘pesticide’ under the Pesticides Act 1974, or is listed in the First Schedule of the Environmental Quality (Schedule Wastes) Regulations.

In simple terms, chemicals hazardous to health are those that can make workers sick, either suddenly or over time. The rest of this article will explain how to identify them in your workplace, what signs to look out for, and what to do if you are unsure.

How to Identify Hazardous Chemicals at the Workplace

Chemicals with Labels and Safety Data Sheets (SDS)

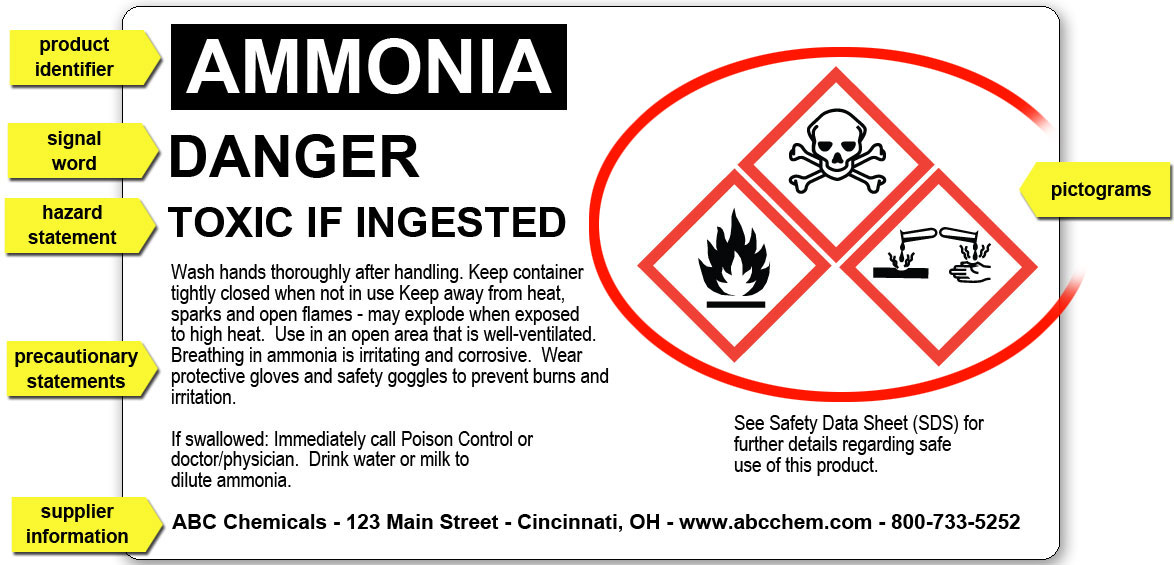

The simplest case is when a chemical is supplied with a proper label and an accompanying Safety Data Sheet (SDS). Labels usually carry Globally Harmonized System (GHS) pictograms such as the skull and crossbones, exclamation mark, or health hazard symbol, along with statements describing the type of hazard and precautions needed.

The SDS goes further by explaining the health effects, handling instructions, storage requirements, and first aid measures. With this information, employers and workers can easily recognize if a chemical is hazardous to health and take the necessary precautions.

Sample Safety Data Sheet (SDS).

Improperly Labeled or Unlabeled Chemicals

In many workplaces, chemicals are not always so well-documented. It is common to find substances transferred into unmarked bottles, such as solvents stored in empty drink containers, or older stock where the original labels have faded or peeled off. Some products are even supplied without an SDS, especially when purchased from small or informal suppliers.

In these cases, the lack of information does not mean the chemical is safe. On the contrary, they should be treated with caution and regarded as potentially hazardous until the proper data can be obtained.

Chemicals Generated by Work Activities

Not every hazardous chemical comes packaged from a supplier. Many are created during work processes themselves. Welding produces metal fumes, woodworking generates dust, diesel-powered equipment releases exhaust, and construction activities can give off silica dust.

These by-products may not arrive with labels or SDS, but they are still considered chemicals hazardous to health because workers can be exposed through inhalation or skin contact. Ignoring them simply because they are a “normal part of the job” leaves workers unprotected against long-term health risks.

Keeping a Chemical Inventory

To bring all this together, workplaces should maintain a complete chemical register. This document should list every substance present, whether it arrives with a label and SDS, is found unlabeled in storage, or is generated during work. Screening can start by using whatever information is available, from labels, supplier documentation, or reliable reference sources.

Practical Warning Signs a Chemical May Be Hazardous to Health

Observable Properties and Odors

Sometimes a chemical reveals its danger through its physical properties. A strong or unusual smell that causes coughing, dizziness, or irritation of the eyes and throat is a clear sign that it may be hazardous. Solvents, for example, often release vapors that can quickly overwhelm workers in confined areas. Similarly, acids and alkalis can give off sharp, pungent odors that irritate the nose and lungs.

Worker Symptoms and Health Complaints

Another important indicator comes from the workers themselves. If employees frequently report headaches, nausea, skin rashes, breathing difficulties, or eye irritation during or after handling certain substances, it is a signal that the chemical may be hazardous to health. These symptoms should never be dismissed as “part of the job.” Even mild irritation, if persistent, may point to harmful exposure that could worsen over time.

Labels, Symbols, and Packaging

In workplaces where labels are present, hazard symbols are a quick visual cue. Containers marked with the skull and crossbones, corrosive symbol, or the health hazard silhouette indicate risks ranging from poisoning to long-term illnesses such as cancer. The condition of the packaging itself can also give hints. Leaking containers, corroded drums, or chemical residues on the outside of bottles all suggest poor management and potential danger.

Environmental and Workplace Clues

Hazards can also be identified by looking at the broader work environment. A workshop with lingering fumes, visible dust in the air, or strong chemical odors likely contains substances hazardous to health. If protective equipment such as gloves, respirators, or fume hoods are consistently used in a particular area, it often means the processes there involve chemicals that can harm workers if controls are not in place.

What to Do After Identifying Chemicals Hazardous to Health

Identifying that a chemical may be hazardous to health is only the first step. What really matters is what comes next, assessing the risk before workers are exposed. In Malaysia, this is done through a Chemical Health Risk Assessment (CHRA), which is a formal evaluation conducted by a registered competent person. The CHRA looks at how the chemical is used, how workers may be exposed, and whether the existing controls are adequate.

Under Regulation 9 of the Occupational Safety and Health (Use and Standards of Exposure of Chemicals Hazardous to Health) Regulations 2000, no employer is allowed to use or permit the use of any chemical hazardous to health unless a CHRA has first been carried out. Failing to comply is a legal offence. This requirement ensures that risks are identified and managed before any harmful exposure occurs, rather than waiting until workers become ill.

A CHRA does more than just tick a compliance box. It provides practical findings, such as whether ventilation systems are effective, whether workers need respirators, or whether safer substitutes should be used. In some cases, the CHRA may recommend a follow-up in the form of Chemical Exposure Monitoring (CEM). This involves measuring the actual concentration of airborne chemicals and comparing it to permissible exposure limits (PEL) to see if workers are being exposed beyond safe levels.

For employers, conducting a CHRA is both a legal duty and a smart business decision. It reduces the risk of occupational diseases, protects workers, and prevents costly penalties or downtime caused by regulatory action. For workers, it offers assurance that their health is not being silently compromised by unseen chemical risks.